Designing a wire clock

Client: Pensa

Machine: The D.I.Wire Plus

Inventing a clock from scratch

Mark Prommel, partner at Pensa, became inspired when he saw the ability of the D.I.Wire being able to create precise, repeated shapes. He began thinking about designs that take advantage of creating forms using single lines and wanted the lines of the object to become integral to the structure of the piece. His final clock, which he calls the D.I.Wire clock, showcases numbers that perfectly utilize the strengths of the D.I.Wire, and would otherwise be very difficult to achieve.

“ When we first got the D.I.Wire up and running, I was blown away by the accuracy, ease of interaction, and immediacy of the results.”

- Mark Prommel, Partner at Pensa

Functioning prototype

Once Mark designed the clock, a functioning prototype was developed. The prototype consisted of wooden pieces CNC’ed at a local woodworking shop, clock-hand fixtures printed on our 3D printer, and numbers and hands bent out using the DIWire. To ensure reliable minute hand movement, the minute hand required shortening. This involved finding the balance between maintaining the desired look of the clock and ensuring the hands were rotating properly. The Pensa team tested different metals as well as different hand lengths before finding the right combination.

How the D.I.Wire Plus was used

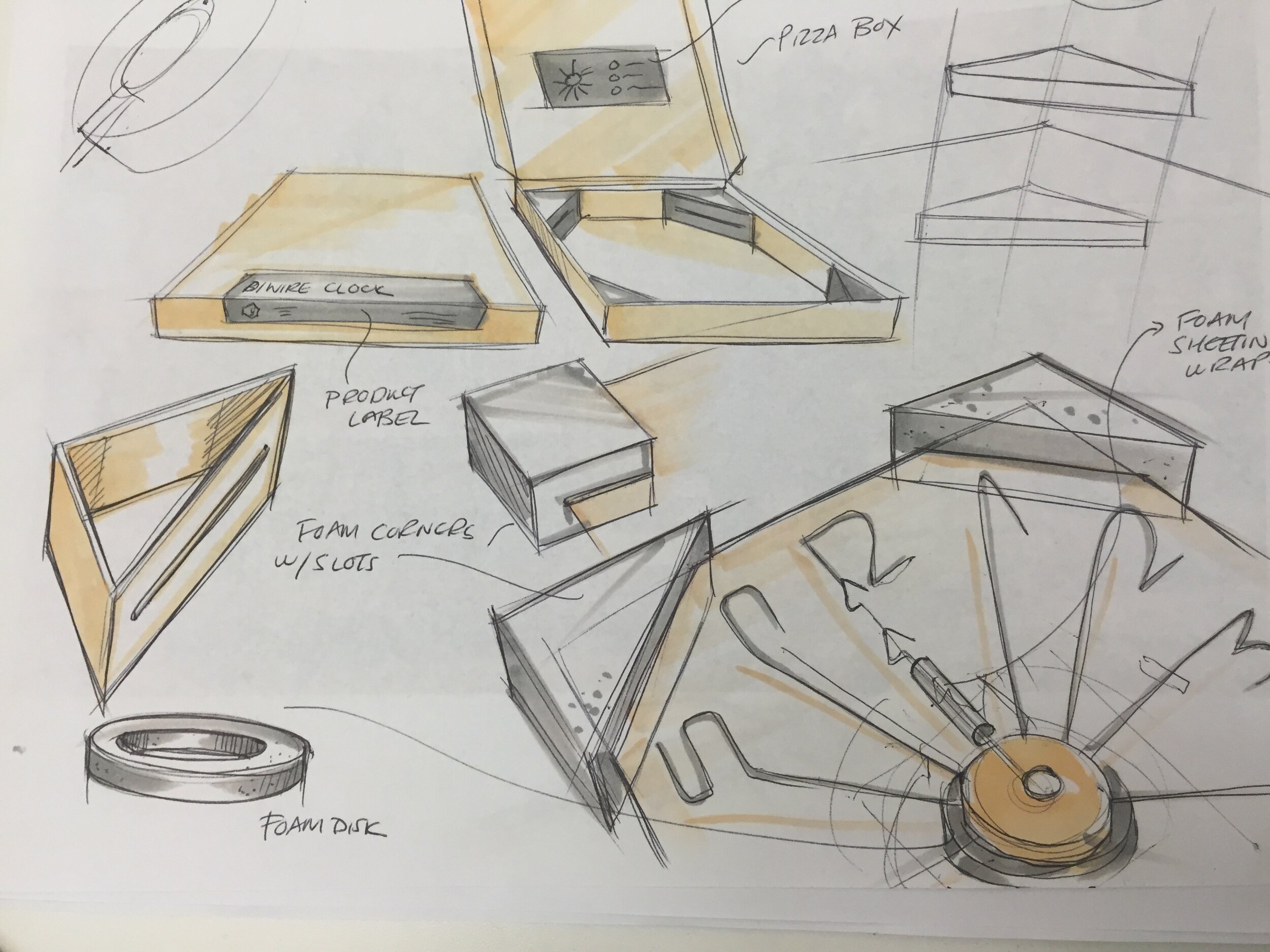

Once the functioning prototype was completed, a batch was produced as rewards for thirty lucky DIWire Kickstarter contributors. Each set of numbers was bent, their ends cut to length on a plotted print-out of the real-sized numbers, and then threaded one by one on a lathe rigged with a rod threader. To achieve the finish, Thomas Callahan from Horse Cycles mounted the numbers to a perforated sheet and applied a black powder coating. Hands were hung by the center point for red powder coating. To create the face, thirty wooden center pieces were glued together. Once the face pieces were set, threaded inserts were screwed into place for number insertion by the clock owner. The minute and hour hands were mounted to a 3D-printed center piece. The clocks were then partially assembled by placing the movement into the wooden piece. Using the D.I.Wire made these iterations fast and easy.

What was the end result

This first batch of clocks were shipped out to the D.I.Wire Kickstarter supporters. The clock garnered such positive attention that the Museum of Modern Art decided to put it into the MoMa Store.